In the context of DTF (Direct-to-Film) UV printing, a substrate is the final object or material onto which the printed design is applied. Think of it as the canvas for your creation.

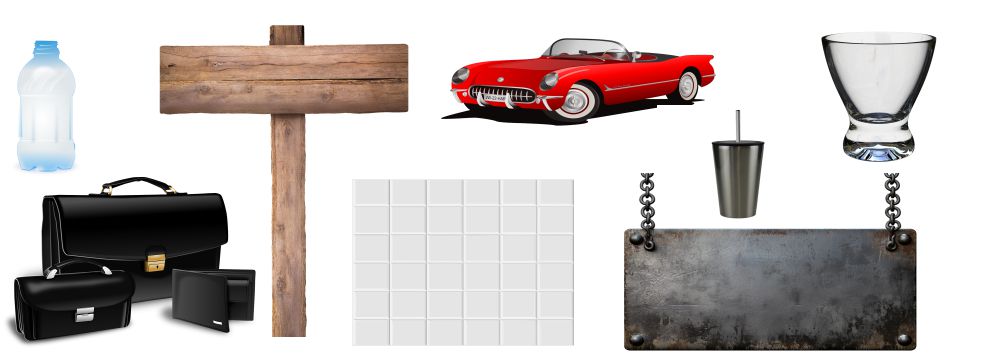

Glass: One of the most popular applications, DTF UV decals adhere exceptionally well to glass surfaces, making them ideal for customizing drinkware, awards, window signage, and decorative items. The clarity and vibrancy of the UV-cured inks create a stunning visual effect on transparent or colored glass. For optimal adhesion on non-porous surfaces like glass, a primer may be recommended by some manufacturers.

Metal: From stainless steel tumblers and aluminum water bottles to coated metal plaques and industrial tags, DTF UV offers a durable and high-quality decoration method. The decals can withstand the rigors of daily use and exposure to the elements.

Wood: Both treated and untreated wood surfaces are excellent candidates for DTF UV printing. This allows for the creation of custom signage, personalized gifts, and unique home décor items. The texture of the wood can sometimes be seen through the decal, adding to the aesthetic appeal.

Plastics: A wide range of plastics, including acrylic, PVC, and polycarbonate, are compatible with DTF UV decals. This opens up applications for phone cases, promotional products, electronic device casings, and retail displays. The flexibility of the film allows it to adhere to curved plastic surfaces seamlessly.

Ceramics: Mugs, tiles, plates, and other ceramic items can be easily customized with DTF UV printing. The resulting products are often dishwasher-safe, although handwashing is typically recommended to prolong the life of the decal.

Leather and Faux Leather: This technology provides a fantastic way to personalize leather goods such as wallets, notebooks, and phone cases with detailed and colorful designs without damaging the material.